At the core of cheesemaking

Producing a consistent and quality curd by controlling the parameters.

A high-performance automated cheese vat for better control over production

The quality of a manufacturing tank is measured by a set of factors facilitating production while guaranteeing yield and quality day after day.

From the design of the vat and its tools to the program that drives it, there are many facets to consider to make the right choice.

We install vats manufactured by Tecnical.

Inside the vat

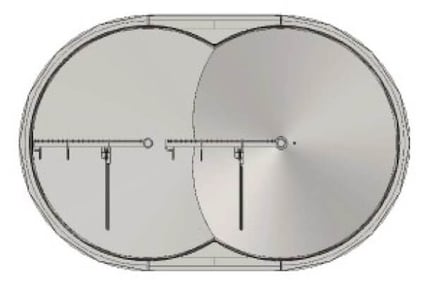

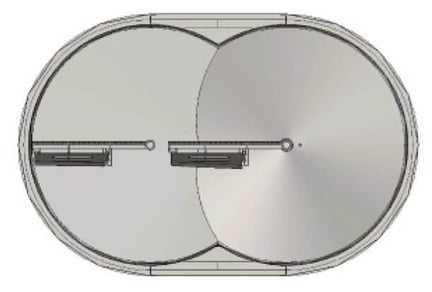

A double-o shaped vat allows for two operations by reversing the direction of rotation of the tools

Cutting

Clockwise rotation, the blades cut the curd

Stirring

Counterclockwise rotation, the agitation paddles mix

Vat work stages

It is in the vat that the transformation takes place.

Filling and coagulation

Milk arrives from the pasteurizer and the vat is filled in a continuous and regular flow for a duration determined by the capacity of the pasteurizer.

Cultures

Cultures and other additives are manually added to the milk during or after filling.

Coagulation

When the coagulant is added, the vat is programmed to uniform the mix and stabilize the milk.

Cutting

The curd cutting program, following the recipe and using efficient cutting tools, ensures a homogeneous cut of the right size.

Vat processing

Emptying

The homogeneous curd-whey mix is gently discharged from the vat to the next stage.

Our approach

Thoroughly understand your cheese, your objectives, and your challenges to find the best solutions

Repeatability

Achieve the target vat after vat for consistent curd.

Yield

Yields are gained or lost in the vat.

Automation

A precise and programmed recipe for each cheese.

Configuration

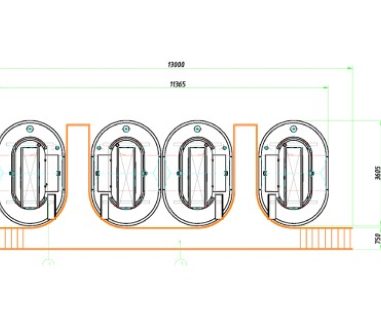

We can install vats in various configurations to integrate them into your factory.

Single vat

Standalone with a control panel and pump.

Multiple vats

For continuous production fed by the pasteurizer.

Production lines

Integrated into an automated production line.

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.