Automatic moulding

Precise and continuous dosing of drained

and pre-pressed curd into moulds.

For continuous moulding and consistent cheeses.

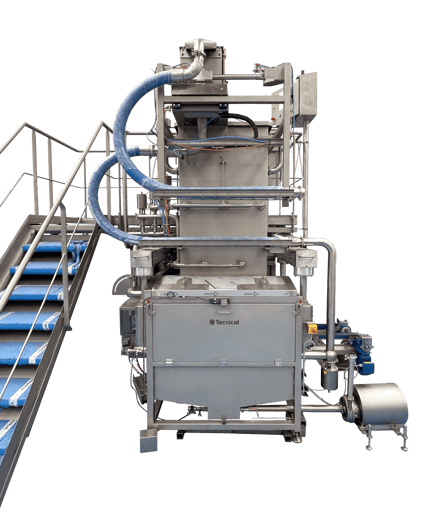

The moulding tower allows a continuous and automated mould filling with precise curd dosing.

Manufactured by Tecnical, this equipment allows the moulding of close-rind cheeses and pressed cheeses with mechanical openings. It is a very flexible solution suitable for a wide range of types and sizes of cheeses.

Working with a moulding tower

The step-by-step process.

Curd input

When the curd is ready in the vat, a pump sends it into the tower. A part of the whey can be pre-drawn into the vat.

Filling

The columns are filled with curd under whey or from above by a continuous whey/curd filtration system.

Pre-pressing

The columns' perforation and the whey level in the pre-press chamber allow the control of the pre-press cheese's moisture.

Moulding

A double gate system cuts the pre-press cheese at a precise weight and places it into the mould.

Features

3 key advantages of working with a molding tower.

Yield

The tower allows a reduction of waste and better control of weights.

Flexibility

Fast format change to produce a wide range of formats and cheeses.

Production capacity

Continuous dosing possible for a dosage of up to 4,500 units/h.

In details

Draining pre-pressing and moulding.

Columns

Allows pre-pressing and gives the pre-cheese a shape close to the mould to limit deformation during pressing.

.jpg?width=432&height=432&name=Fromagex%20website%20assets%20(2).jpg)

Moulding

Volumetric moulding by a double guillotine system allows to have a precise weight.

.jpg?width=432&height=432&name=Fromagex%20website%20assets%20(1).jpg)

Cleaning

Connected to the plant cleaning system (CIP).

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.