Moulding while respecting the curd

The moulding step is crucial to obtain the desired moisture content and consistent weights.

A controlled moulding

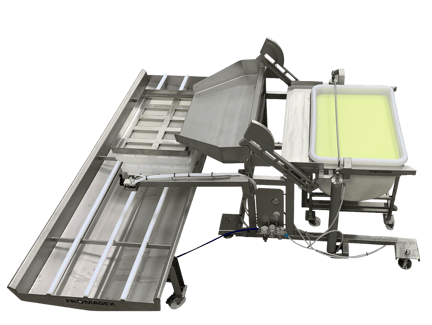

A moulding station for the coagulation vats allows rapid moulding without a pump to preserve the integrity of the curd. The weight per cheese is easy to adjust with the amount of milk per vat.

This tipping station is intended for use by a single operator and with a small footprint.

Moulding steps

Our moulding system ensures consistent coagulation, cutting, and moulding times while providing the flexibility to scale production volumes.

Filling the Vat

The volume of the vat is adjusted according to seasonality of the milk to always produce the same number of cheeses.

Coagulation in the vat

Rennet is added to the vat. Once the curd is ready, it is cut and stirred according to your recipe.

Pouring

The vat is loaded into the tipping station and the operator will control the pouring speed for easy moulding.

Distribution in moulds

Using a distributor, the cheesemaker evenly distributes curd into the block mould. Each vat consistently corresponds to a specific number of block moulds, ensuring uniform curd volume per hoop.

Draining

Block moulds are ready to be stacked for draining. The whey is collected using the draining table.

Productivity Assets

Designed for small and medium-sized cheese factories, this system allows you to achieve your productivity and quality goals.

Yield

Gentle handling of the curd to maximize yields.

Consistency

Each vat, each mould has the same uniform result.

Flexibility

Work in small vats to easily adjust production volumes.

In details

Easy to use, our tipping station offers the following features:

.png?width=432&height=432&name=Fromagex%20Stores%20(20).png)

Speed control

With the control of the pneumatic cylinder the cheesemaker manages the dispersion of the curd.

.png?width=432&height=432&name=Fromagex%20Stores%20(22).png)

Adapted to our equipment

Vats, moulding tables, block moulds and distributors

.png?width=432&height=432&name=tipping-station_1%20(1).png)

Moulding by chute

No pump to respect the fragility of the curd.

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.