Racks for ripening and brining

Stainless steel wire racks are manufactured to the cheese specifications for optimal performance.

.jpg?width=432&height=288&name=iStock-486648255%20(1).jpg)

For a homogeneous rind development

The racks are assembled in stacks, leaving sufficient space for uniform ventilation of each cheese.

Racks constructed from stainless steel wire are a flexible solution that optimizes space in the factory, from storage to use.

Key Elements

Several factors to be considered when selecting an aging rack.

Cheese

Cheese type, size and weight are factors that determine the rack configuration.

Demoulding

During demoulding cheeses are placed on racks. The size and assembly of the moulds often determine the size of the rack.

Usage

the way racks are used and handled in the factory influences the choice and design.

Types of racks

Inox rack is easy to custom-make, it adapts to all your needs. Contact-us to study your project.

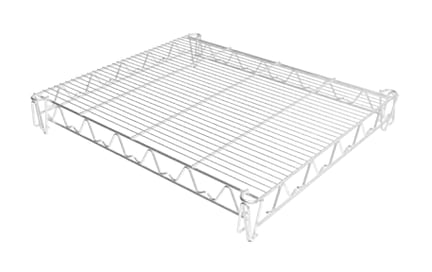

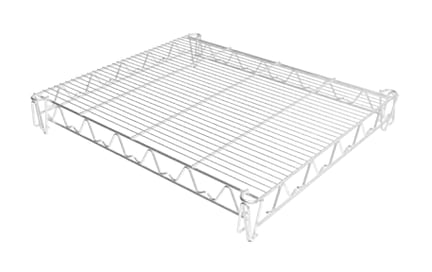

Standard racks

Simple racks in standard formats in stock or made to order.

Reinforced racks

Racks with gallery for brining or heavy loads.

Special racks

Adapted for special shapes or fragile cheeses.

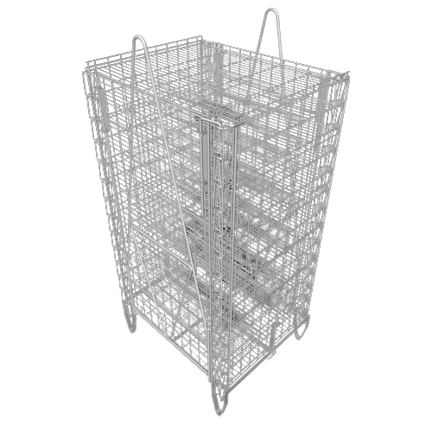

Brining racks

We also offer brining racks, lifting cages, and other accessories adapted for brine.

Adaptation for your plant

We manufacture racks suitable for mechanization: racks at demoulding, stacking-unstacking, and flipping.

Plastic legs

Racks with plastic legs are a good solution for easy identification.

Rack bases

Bases suitable for mechanization.

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.