Pressed cheeses perfectly shaped

Microperforated moulds provide the best results and the best pressing conditions.

Microperforated mould: the pressed cheese ally

Master the moulding of pressed cheeses with the microperforated mould, the essential tool that combines versatility and performance.

Working with microperforated moulds

Microperforated moulds offer several advantages

No cheese cloth

The curd drains evenly through the microperforations without the use of washable natural or disposable synthetic cloths. This saves time, material, has a lower carbon footprint and a better result for the cheese.

A versatile solution

Microperforated moulds are used for a wide variety of cheeses and applications. The size and number of perforations as well as the various shapes and dimensions allow for use in draining and acidification.

Curd at moulding

At moulding step, the pre-drained curd is the raw material that interests the mould manufacturer. From salted cheddar curd to square pre-pressed curd blocks to be placed in a round mould, we know how to find the appropriate moulding solution.

Adjusted pressing

When the cheese comes out of the mould, it must be perfect, with a uniform rind and the cheese conforming to the target, curd closed or slightly open.

Our offer

The choice of mould grooving will give your cheese its distinct outside appearance. Two categories of moulds are possible to adapt to the production.

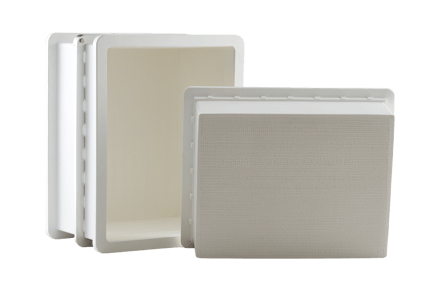

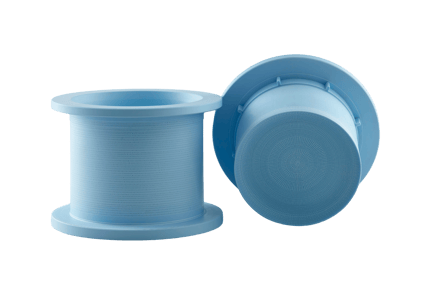

Individual moulds

Injected single-piece moulds that are easy to handle.

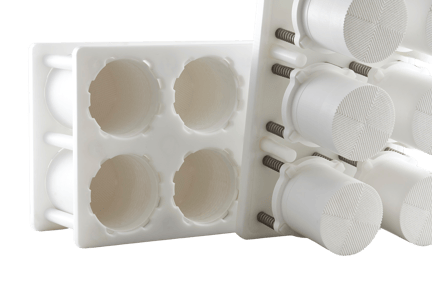

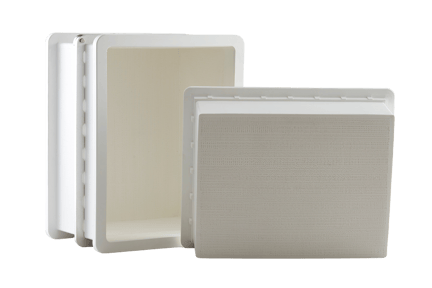

Block-moulds

Moulds for automated production lines.

Mould selection

Here's how we work with you to choose the right mould.

Case study

We take the time to fully understand the needs of the cheese, your way of working, and your future plans in order to recommend the right mould.

Trials

From theory to practice, it is essential to do trials to validate that the moulds give the expected results and adapt them as needed.

Design & offer

We present you with a design and an offer tailored to your production method.

Production

With an approved plan, we produce the moulds in compliance with the specifications.

Standard moulds

We maintain a stock of standard moulds for small projects.

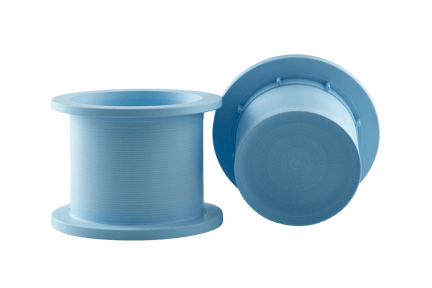

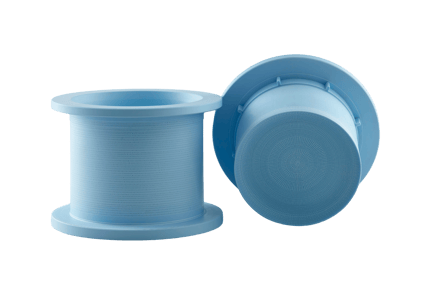

Cylindrical moulds

For round wheels with sharp edges.

Gouda moulds

For wheels with rounded edges.

Rectangular moulds

For cheddar and other block-style cheeses.

Your everyday challenges

When you share your goals and challenges with us, we respond by analyzing your needs and proposing high-performance, tailored solutions.